1. Introduction to Polyurethane Packaging

Polyurethane packaging is widely recognized for its versatility and reliability across various industries. While many are familiar with polyurethane for its use in furniture, bedding, and insulation, it has also become a popular material in packaging, particularly for fragile or lightweight items. Polyurethane packaging, including Polyurethane foam inserts, offers a high level of protection and flexibility, making it an ideal choice for packaging products in sectors such as electronics, jewelry, ceramics, and medical supplies. This article explores the benefits of using Polyurethane packaging, its applications, and how it can enhance your product protection strategy.

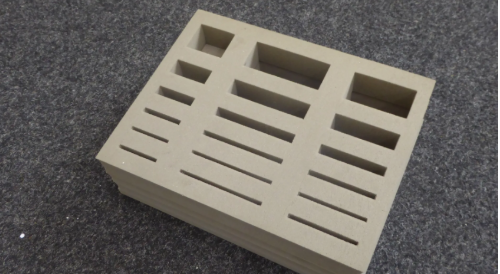

Polyurethane foam is particularly known for its adaptability and multi-purpose use. It can be molded into different shapes, including blocks or custom designs such as the popular “egg box” foam, which features a series of peaks and troughs. These unique characteristics allow Polyurethane packaging to securely hold items of various shapes and sizes. Whether you are looking for a lightweight, flexible, or resilient material to safeguard delicate products, Polyurethane packaging provides a versatile solution.

2. Benefits of Polyurethane Packaging

2.1 Lightweight and Flexible Protection

One of the most significant benefits of Polyurethane packaging is its lightweight nature. This makes it particularly suitable for businesses that need to keep shipping costs down without compromising on protection. The flexibility of Polyurethane foam inserts allows it to be customized to fit a wide range of product shapes and sizes. Whether you need cushioning for electronics, medical devices, or luxury goods, Polyurethane packaging can be designed to meet your specific needs.

Polyurethane foam inserts are also highly resilient, meaning they can absorb shocks and impacts during transportation. This cushioning effect reduces the risk of damage to fragile items, ensuring that products arrive at their destination in perfect condition. The ability to provide multi-drop protection makes Polyurethane packaging an excellent choice for industries that require repeated handling and shipping.

2.2 Customizable Designs for Various Applications

Polyurethane packaging is highly adaptable, allowing for custom-designed inserts that perfectly fit the contours of your products. Custom-fit Polyurethane foam inserts offer a snug and secure fit, providing optimal protection. This is particularly important for industries that handle delicate or high-value items, such as electronics, jewelry, ceramics, and art.

For example, Polyurethane foam inserts can be tailored to create compartments for holding electronics or medical devices in place. This level of customization ensures that each product is safely secured during shipping and handling, minimizing the risk of damage. Whether you need simple blocks or more intricate designs, Polyurethane foam can be easily shaped and cut to meet your specifications.

2.3 Durability and Resilience

Polyurethane packaging is highly durable, ensuring that your products are protected even after multiple shipments or handling. This long-lasting material can withstand repeated use without losing its protective qualities, making it an ideal choice for businesses that need to ship items multiple times. Polyurethane foam inserts provide continuous impact absorption, helping to maintain the integrity of your products during transportation.

Additionally, Polyurethane foam is resistant to dust, moisture, and environmental changes, further enhancing the protection it offers. This makes it particularly suitable for industries that deal with sensitive or fragile items that need to be stored or transported under varying conditions.

2.4 Eco-friendly Options for Sustainable Packaging

In today’s environmentally conscious world, sustainability is a key consideration for businesses. Polyurethane packaging can be produced in a more eco-friendly way, using recyclable or biodegradable materials. Some manufacturers offer Polyurethane foam inserts made from sustainable resources, helping businesses reduce their environmental impact.

By choosing eco-friendly packaging solutions, companies can demonstrate their commitment to sustainability while still ensuring their products are protected during transportation. Polyurethane packaging offers a balance between performance, protection, and environmental responsibility, making it a great choice for businesses looking to enhance their green credentials.

3. Applications of Polyurethane Packaging

Polyurethane packaging is used across a wide range of industries, offering tailored solutions for different packaging needs. Some of the most popular applications of Polyurethane packaging include:

3.1 Electronics and Medical Devices

Polyurethane foam inserts are commonly used in the electronics and medical industries to protect delicate components. Electronic devices such as smartphones, laptops, and cameras require secure packaging to prevent damage from impacts or moisture. Polyurethane foam can be molded to create custom compartments that hold these items in place, offering protection during transit.

Medical devices, which are often high-value and sensitive, also benefit from the use of Polyurethane packaging. From surgical instruments to diagnostic equipment, Polyurethane foam inserts provide the necessary protection against shocks and vibrations, ensuring that these critical products reach their destination safely.

3.2 Jewelry and Ceramics

Polyurethane packaging is also widely used in the jewelry and ceramics industries, where delicate items need to be securely protected. Jewelry pieces, including rings, necklaces, and bracelets, can be safely stored and transported in custom-designed Polyurethane foam inserts that prevent movement and reduce the risk of damage.

Similarly, ceramic items, which are often fragile and prone to breakage, benefit from the cushioning and shock-absorbing properties of Polyurethane foam. Custom inserts designed for ceramics can hold items in place and provide a secure, impact-resistant barrier that helps preserve their integrity.

3.3 Art and Collectibles

For fine art and collectibles, Polyurethane packaging offers the ultimate protection. From paintings and sculptures to rare artifacts, Polyurethane foam inserts can be custom-shaped to fit the contours of each piece, ensuring that valuable items are kept safe during shipping or storage. The foam’s ability to absorb shock and impact makes it an ideal choice for these high-value items, which require extra care and attention during transportation.

3.4 Industrial and Automotive Components

Polyurethane packaging is not limited to fragile or delicate items; it is also used in the packaging of industrial and automotive components. For example, automotive parts, tools, and machinery components are often shipped in custom-designed Polyurethane foam inserts that ensure they are securely packed and protected from damage during transit.

These inserts are highly resilient and can withstand the rigors of multiple drops, making them ideal for industries that require reliable, repeatable performance.

4. The Complete Packaging Solution

Polyurethane packaging is not only effective in providing protection, but it also simplifies the packaging process. By offering a complete solution, manufacturers can supply both the outer carton and internal Polyurethane fitments, ensuring that the strength of the carton is matched with the protective qualities of the Polyurethane foam inserts.

Choosing a single supplier for both packaging components streamlines the design and ordering process. This reduces the complexity of sourcing multiple suppliers, making the packaging process more efficient. Furthermore, buying from a single source helps to avoid issues such as unbalanced stock levels, providing businesses with a reliable and consistent supply of packaging materials.

In addition to Polyurethane foam inserts, many suppliers also offer other packaging products, such as bubble wrap, tape, and cartons, to provide a comprehensive solution for your packaging needs. This all-in-one service allows businesses to focus on other aspects of their operations while ensuring their products are safely and securely packaged for delivery.

5. Conclusion

Polyurethane packaging is a versatile and effective solution for protecting products across a variety of industries. With its lightweight, flexible, and resilient nature, Polyurethane foam inserts provide excellent protection for delicate and fragile items, reducing the risk of damage during transportation and handling. Its customizability, durability, and eco-friendly options make it a popular choice for businesses looking for a reliable and sustainable packaging solution.

Whether you are packaging electronics, jewelry, ceramics, medical devices, or industrial components, Polyurethane packaging offers a tailored solution to meet your specific needs. By choosing a complete packaging service that includes both the outer carton and internal fitments, businesses can simplify the packaging process and ensure their products are securely protected. As packaging continues to play a critical role in product safety and presentation, Polyurethane packaging remains an invaluable tool for businesses looking to safeguard their goods and enhance their overall product experience.

6. Benefits of Polyurethane Packaging

- Enhanced Protection: Polyurethane foam inserts offer superior cushioning and shock absorption, protecting delicate and fragile items from impacts during transit.

- Customizable Designs: Polyurethane packaging can be tailored to fit the unique shape and size of each product, ensuring optimal protection.

- Lightweight and Flexible: The lightweight nature of Polyurethane foam reduces shipping costs, while its flexibility allows it to be molded into various shapes for different applications.

- Eco-Friendly Options: With the growing demand for sustainable packaging solutions, Polyurethane packaging can be produced using recyclable or biodegradable materials, supporting eco-conscious businesses.

- Durability: Polyurethane foam maintains its protective qualities over time, making it suitable for repeated use in multi-drop packaging scenarios.